Working of concentrator photovoltaics in steps

In the process of solar concentrating photovoltaic power generation, there is a phenomenon that the power generation efficiency decreases with the increase of battery temperature. If the liquid cooling method is used to cool the battery, heat can be obtained and the battery temperature can be reduced, so as to improve the power generation efficiency.

Step 1: Sun chasing system:

No matter what system, it can use the day tracking system to improve its output.

In the case of silicon, the installation of the sun chasing system can increase the daily output Watts by about 25%.

In the case of GaAs, the addition of sun chasing system can increase the daily output Watts by about 100%.

Note: because the efficiency of monocrystalline polysilicon is relatively low, the required support, power distribution materials, civil engineering and wages will double, and the silicon crystal itself will accept more ultraviolet rays and higher temperature due to long-time sun chasing, so its risk needs to be evaluated. In addition, the panel area will be larger (at the same output Watt), so its wind resistance will be poor.

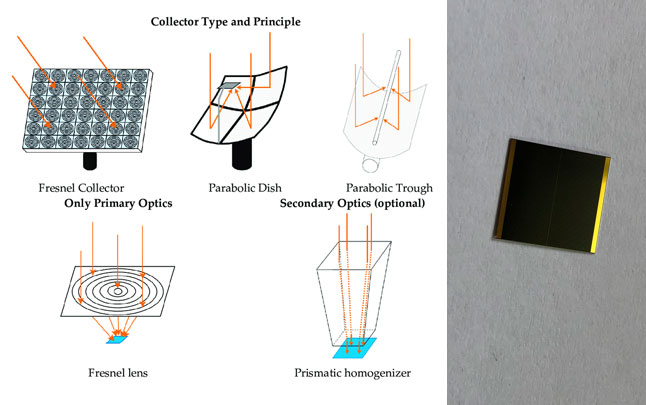

Step 2: Focus:

The solar light is focused 500 times with a lens, so that the area of solar chip is reduced to 1 / 500 of the original.

However, single crystal polycrystalline silicon and thin film solar chip materials can not bear the high temperature generated by high focusing, so this technology can not be used

Step 3: High performance chip:

Whether in silicon material or GaAs material itself, the photoelectric conversion efficiency is improved by using process and other epitaxial technologies,

So as to increase output efficiency.

Comparison between monocrystalline polysilicon,GaAs solar system and high concentration type

Monocrystalline polysilicon high condensing type, conversion efficiency 14-18%, GaAs solar conversion system efficiency 39%.