The strategy of RF components such as high pass power amplifier (PA), the global leader of mobile phone chips, is changing from the current CMOS process of TSMC to the GaAs process. The foundry factories such as Acer and Wenmao will benefit, but the impact on TSMC films remains to be seen. In 2014, Qualcomm launched its own RF component solution "rf360", which is a PA with semiconductor CMOS process. It has the advantage of low cost. It is manufactured by TSMC in an eight inch factory, and then shipped with its own mobile phone chips. It is different from other pa manufacturers such as skyworks, Avago, RFMD, etc., which use gallium arsenide (GaAs) process.

But, a couple of days ago, Qualcomm announced a venture with TDK, a serious Japanese component manufacturer, to line up a replacement company "rf360 holdings Singapore" in Singapore. EPCOS, a subsidiary of TDK, which is engaged in RF module business, will split a part of its business to make "rf360", which suggests that the layout of RF components representing Qualcomm are going to be changed. In response, Steve Mollenkopf, chief executive of Qualcomm, said that the "gallium arsenide PAS" (gallium arsenide PA) launched in cooperation with TDK are going to be produced in 2017, which may be a more appropriate time point, and that we will search for an appropriate application market at that point .

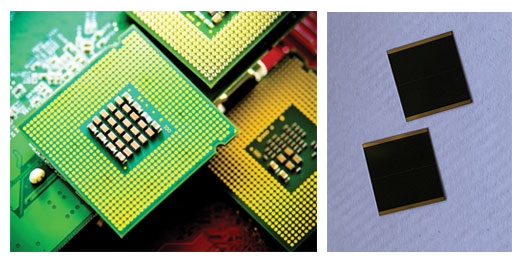

With the rapid development of mobile terminals, similar to WiFi and LTE, the technical requirements for RF front-end are also higher and higher, and RF components including power amplifiers, antenna switches, low noise amplifiers cover more frequency processing channels than before. In this case, more and more RF component manufacturers are looking for more cost-effective solutions. At present, most of the devices on PCBA can be made of silicon, only the RF part can't be used. The mainstream technology is gallium arsenide (GaAs). However, due to the scarcity of materials required by the GaAs process, both the material cost and manufacturing cost are relatively high, and the requirements for the production line are also very high. It is understood that the recent shortage of 4G LTE PA is mainly due to the limitation of GaAs process by materials, which can not meet the production capacity. The industry has been focusing on silicon for a long time, because the material of silicon is sand, which is inexhaustible. Moreover, the CMOS process is also the most mature for the wafer factory, which can directly use wafer from the wafer factory. Carson, senior marketing director of Qualcomm, said that the main control end of RF front-end system mainly lies in the data machine platform. At present, CMOS technology has been widely used in LTE data machines. Therefore, if the virtual part of RF front-end can also be imported into CMOS technology, the integration of LTE platform control interface will be greatly improved.