Arsenide Formula is III - V compound semiconductor materials. It has some properties superior to silicon and has become an important semiconductor material second only to silicon.

The epitaxial growth of GaAs can be divided into gas phase epitaxy and liquid phase epitaxy. The obtained epitaxial layer is superior to bulk single crystal materials in purity and crystal integrity. The general vapor phase epitaxy process is GA / ascl3 / H2 method, and the alternative processes of this method are GA / HCl / AsH3 / H2 and GA / ascl3 / N2 method. In order to improve the quality of gas phase epitaxial layer in GA / ascl3 / H2 system, epitaxial growth processes at low temperature and low pressure were also studied. The liquid phase epitaxy process is to cover the substrate surface with GA / GaAs molten pool, and then grow the epitaxial layer by cooling. It can also adopt the temperature gradient growth method or the electric epitaxy method with DC applied. Vapor phase epitaxy is more widely used than liquid phase epitaxy in the manufacture of devices, especially microwave devices. Liquid phase epitaxy can be used to manufacture heterojunctions (such as GaAs / alxga1 XAS), so it is an important means to manufacture GaAs double heterojunction lasers and solar cells.

Arsenide Chemical formula: GaAs

Molecular weight: 144.645

CAS No.: 1303-00-0

EINECS No.: 215-114-8

Density: 5.31g/cm3

Melting point: 1238°C

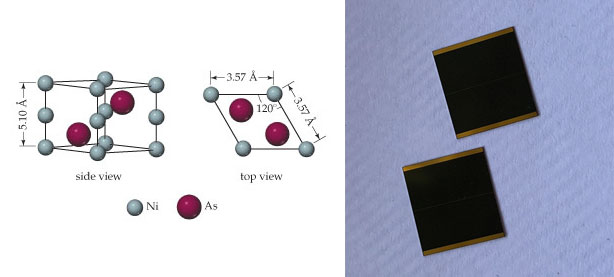

Refractive index: 3.57

Relative permittivity: 13.18

Electron affinity: 4.07 eV

Lattice energy: 5.65×10-10m

Forbidden band width: 1.424e (300K)

Electron mobility: 8500 cm2/(V·s) (300 K)

Appearance: black gray solid

The toxicity of GaAs has not been fully studied. Because it contains as, studies have shown that as is highly toxic. However, because the GaAs crystal is very stable, if the body absorbs a small amount of GaAs, it can be ignored. When the wafer polishing process (grinding GaAs wafer to make the surface particles smaller), the surface area will react with water to release or decompose a little as.