With the deployment of national space strategic planning, space satellite technology has become the main field of development in the 21st century. As the main part of space satellite, space power supply, its photoelectric conversion efficiency is the key factor in the development of space technology. The preparation of multi junction solar cells can effectively improve the photoelectric conversion efficiency, but the preparation process is complex and the cost is high, so it is difficult to be used in industrial production.

The surface microstructure can inhibit the reflection of incident light, enhance the light absorption intensity on the surface of the battery absorption layer, and improve the photoelectric conversion efficiency of the battery. Therefore, researchers are committed to the anti reflection research of surface microstructure. The surface of GaAs / Ge single junction heterostructure battery was processed by appropriate processing environment and optimized femtosecond laser process parameters. At the same time, flash test for si and gaas cell. The interaction between different microstructures and incident light in different bands, and the formation mechanism of different microstructures is explored through experiments.

The main conclusions are as follows:

(1) the effects of different processing environments (air, ethanol and distilled water) on the microstructure of GaAs / Ge single junction heterostructure cells prepared by femtosecond laser were studied. The results show that the microstructure prepared in distilled water environment is 1 ~ 2 orders of magnitude smaller than that in air environment, and its distribution is uniform, and its depth range is controlled at 100 ~ 350 nm; The microstructure prepared in distilled water environment is more complex than that in ethanol environment. The number density of protrusions is large, and there are many nano holes around the protrusions.

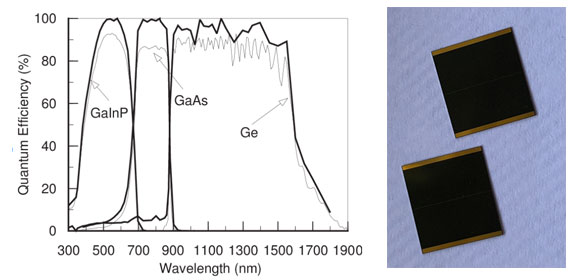

(2)In distilled water environment, the effects of femtosecond laser process parameters such as energy density and scanning speed on the morphological changes of microstructure were studied, and the best process parameters (7.9j / cm2,2.2mm / s) were obtained. Composite nano structures (CNS) were successfully prepared on the surface of GaAs / Ge single junction heterostructure cells. The CNS structure is composed of nano pores and nano protrusions, and the size range is controlled within 300 ~ 500 nm. The average reflectivity (300-1700nm) of the battery surface covered by the CNS structure is reduced from 30.84% to 8.9%. On the one hand, the antireflection mechanism of CNS structure is its multiple reflection of short band incident light, on the other hand, it acts as an effective refractive index layer to antireflection of long band incident light.

(3) One dimensional micro / nano composite grating structures (1D CGS) were prepared on the surface of GaAs / Ge single junction heterogeneous solar cells irradiated by femtosecond laser in air environment, so that the average reflectivity of the cell surface decreased from 30.84% to 7.17% in the band of 300-1700nm. At the same time, a similar grating structure was prepared on the surface of GaAs double junction battery, and the average reflectivity of the double junction battery surface was reduced from 38.36% to 9.09% in the same wide band range. The antireflection mechanism of 1D CGS structure is the combination of light trapping effect and effective medium effect. The micron grating structure forms light trapping effect, and the composite nanostructure inside the grating structure forms effective medium effect.