Inspired by sunflower, scientists have developed a sunflower shaped solar concentrator photovoltaics. They say the concentrator will revolutionize the solar field. The new solar concentrator uses several mirrors to focus suncore on the converter chip. Experts say the solar concentrator photovoltaics could be used to power remote areas.

Scientists hope the project of concentrator photovoltaics will develop affordable optoelectronic systems that can collect 80% of the suncore and convert it into electricity. The system can be built in any area that lacks sustainable energy, potable water and cold air at a cost of one-third that of a similar system. The prototype of this concentrator photovoltaics system uses a huge parabolic cylindrical reflector and consists of several small mirrors. They're connected to a tracking system. The tracking system determines the optimal angle according to the position of the suncore.

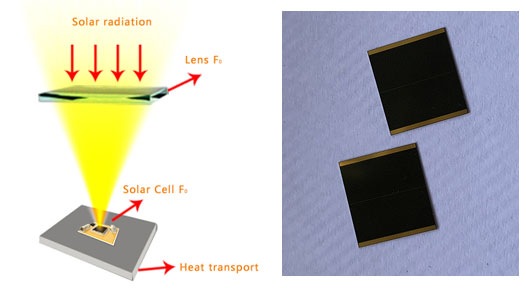

Parabolic cylindrical reflectors reflect suncore to a number of microchannel liquid cooled receivers with optoelectronic chips. The size of each chip is 1 × One centimeter, if calculated according to the daily sunshine time of 8 hours, can generate an average of 200 to 250 watts of electricity. According to this week's news, the Swiss Council for technology and innovation has awarded a 3-year research grant of US $2.4 million to scientists from IBM Research Institute, solar energy technology provider air light energy, the Federal Institute of technology in Zurich, the Kurt University of Applied Sciences and the Brooks interstate Institute of technology. They will be responsible for the research and development of this project. This project is called economic high concentrator photovoltaics power generation and photothermal system (hereinafter referred to as HCPVT).

There are hundreds of concentrator photovoltaics multi junction gaas solar cells in the whole receiver of hcpvt system, which can provide 25 kW power. The photoelectric chip is installed in the microstructure layer, which is responsible for transporting the liquid coolant to the position only tens of microns away from the chip. The function of the coolant is to absorb heat, and the efficiency is 10 times of the current system. Bruno Mitchell of IBM Research said:; We plan to use three junction photocell on the microchannel cooling module, which can directly convert more than 30% of the collected suncore into electricity, and allow the waste heat recovery efficiency to reach more than 50%.

It's a very modest innovation based on decades of experience in lightweight and high-strength concrete materials used for bridges.The design of the whole concentrator photovoltaics system is very simple. Replace expensive steel and glass with cheap concrete and simple pressed metal foil.