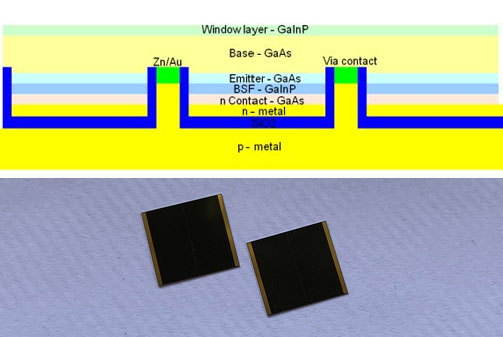

Thin film GaAs solar cells use through-hole contacts to form back contact solar cells to eliminate the light blocking effect and enhance photon recovery at the same time. This paper discusses the manufacturing process and the characteristics of the fabricated devices. According to our measurements, in a 5 × A conversion efficiency of 6.5%, an open circuit voltage of 0.95 V and a current density of 8.6 MA / cm2 under single sunlight were obtained in a 5 mm gaas solar cells.

A newly developed microsystem enabled, back contact, shadow free GaAs solar cell. Using microsystem tools, we created a solid 3 μ M thick equipment with transverse dimension of 250 μ m、500 μ m. 1 mm and 2 mm. The results of manufacturing process and characteristic test are discussed below. The transverse dimension of the most efficient gaas solar cell is 500 μ m. The conversion efficiency is 10%, the open circuit voltage is 0.9 V, and the current density under single sunlight is 14.9 MA / cm2.

The new proposed diffusion driven charge transfer way can realize the paradigm shift of optoelectronic device design by changing the present injection principle and device structure. DDCT injection technology is predicated on bipolar electron and hole diffusion current, which is employed to electrically inject charge carriers into the active region (AR) outside the contact . during this paper, we study an interdigital back contact DDCT light emitting diode (LED) supported GaInP / GaAs double heterojunction (dhj) structure, which consists of transverse heterojunction (LHJ) above uniform ar. The structure adopts single-sided electric injection, which is suitable for large-area applications and thin-film devices with near surface ar. Our analysis supported charge transfer simulation shows that compared with the normal structure, this structure allows simpler current diffusion and lower surface recombination, leading to very high internal quantum efficiency (IQE) and quite 99% injection efficiency. especially , we studied the effect of using new structures to enhance the efficiency of LEDs, making them closer to the edge of electroluminescent cooling (ELC). Results it's predicted that the interior power conversion efficiency of ddct-led is above that of unified, which greatly exceeds the efficiency of traditional reference equipment, highlighting the new possibilities provided by DDCT equipment, especially the high-power ELC at temperature .