The GaAs/Ge solar cabin cell made with germanium as the substrate has the same performance as GAs/GaA, and the cell is close to the mechanical strength, and the monolithic cell area is larger. In the space application environment, the hang-up enclosure value is less than the high-performance decline of the silicon battery. Its application cost is close to the same power silicon panel, which has been used in various types of military satellites and some commercial satellites, and has gradually become the main space power supply.

After more than 40 years of development, solar cells have been proven to be very effective power sources for various types of spacecraft. SiGaAsGaAs multi-junction IPCISCInSe2) and CdTe cells have been studied and applied. Until the 1980s, silicon solar cells have been due to their mature technology and stable performance. It is the main space power source. Through IBM's initial attempts and the efforts of Hughes, Lincoln Laboratory, etc., people gradually realized that GaAs solar cells are the new development direction of space power sources. From the early 1980s, the US Air Force funded the MANTECH program and Applied Solar's research shows that GaAs solar cells have good application characteristics. Progressive research has proved that GaAs/Ge cells made of heteroepitaxial GaAs on a Ge substrate have the same characteristics. InP cells have excellent radiation resistance, but The current manufacturing cost is too high. CIS and CdTe thin-film batterys have low conversion efficiency and are only used for some special-required panels. Si cell technology continues to develop conversion efficiency up to 15 latitudes or even close to 18%, but its poor radiation resistance makes its application limited. The cell will be more used in low temperature and low illumination conditions. The structure of the loose junction GaAs solar cell of the nGaAsorGs2GaAs/Ge cell is shown in Figure I [z] mainly includes the GaAs buffer layer, n-type GaAs base, P-type GaAs emitter and AIGA. Window The substrate uses GaAs or Ge wafers. In the early days, liquid phase epitaxy was mostly used in the preparation of cells. Now, the MOCVD method is basically used, also known as the MOVPE method. Because germanium has higher mechanical strength than gallium arsenide, the cleavage rate is smaller and it is easy to obtain large-scale high.

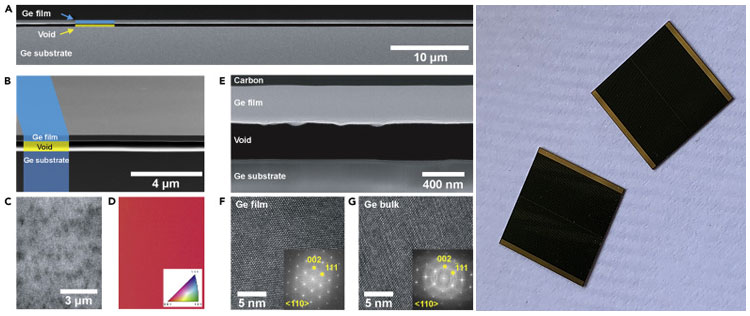

The use of germanium instead of gallium arsenide as the substrate of the solar cell can produce a thinner substrate, reduce the weight of the cell, reduce the production cost, and increase the area of the monolithic cell. At present, it has been widely used.